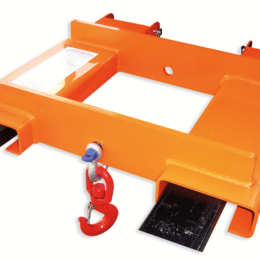

Mechanical and manual Handling Equipment including all pallet trucks, pump trucks, scissor-lift tables, stackers, forklift truck attachments and EP Equipment

Welcome to Handling Equipment Online. With over 110 years’ worth of experience and knowledge, we have the experience that really counts. So, if you’re looking for handling equipment, then make us your one stop shop! With everything from pallet trucks to 18 tonne forklifts, we have everything that your business needs – enquire online today!